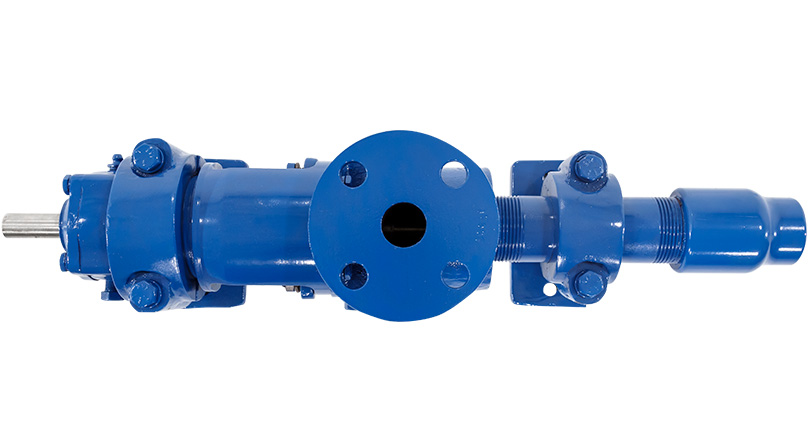

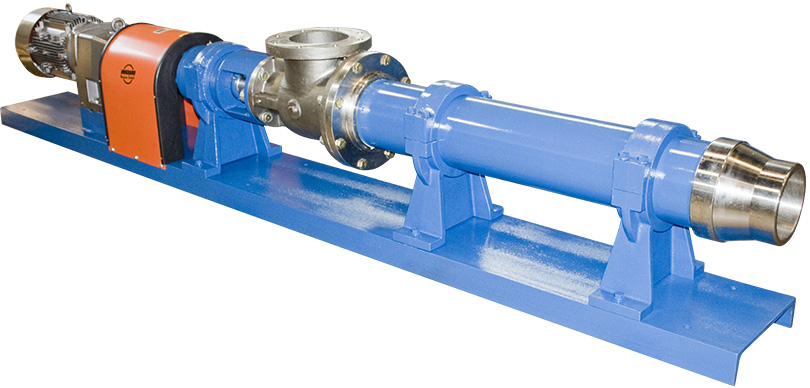

Liberty LL2 Series Progressive Cavity Pump

The Liberty Process LL2 Progressiv Cavity Pump is an ideal low-flow Progressive Cavity Pump for polymer feed, chemical feed and sampling/dosing applications. The LL2 design has been in use in the chemical injection and wastewater polymer feed industry for decades by offering precise, pulseless fluid injection control that only a PC Pump can provide. Polymer injection in wastewater systems require a precise dilution of polymer in suspension to work correctly. The LL2 PC pump is in use in many wastewater polymer and chemical applications in America today.

LL2 series pumps and parts are direct drop in aftermarket replacements that interchange with the *Moyno® L2 Series, *Tarby® TL2 Series and *Continental® CL2 Series.

The LL2 is a standard flanged pump with a low-flow design (.260 gpm/100 revolutions) manufactured in cast iron or 316 stainless steel casings and designed in 1, 2, and 3 stages for 60, 120, and 180 psi discharge pressures respectively. The units modular design with simple pinned joint drive assembly makes it a cost-effective choice for low-flow pumping applications.

The standard LL2 seal design is a set of gland packing with a Lantern Ring Set and flush connections. Mechanical seal options are readily available. Rotors are typically hardened tool steel or 316 stainless steel with a hard chrome plating specification. All other wetted parts are either carbon steel or 316 stainless steel. Stators are available in many elastomer materials such as Buna Nitrile, Natural Rubber, EPDM and Viton.

The LL2 represents one of the most popular progressive cavity pumps available in the wastewater industry. The LL2's pulseless design has good flow capacity and represents an industry standard in polymer injection for wastewater applications.

Contact a Liberty Process representative today for more information about the LL2.

Liberty Series - LL2 - Technical Data

| Flow Rate | .40 - 3 GPM |

|---|---|

| Pressure | 0 - 180 PSI |

| Seal Options | Packing and Mech. Seal |

| Base Options | Steel and Stainless Steel |

| INLET / OUTLET | 1" / 3/4" |

| Rotors | Tool Steel & Stainless Steel, Chrome-Plated |

| Stators | Buna / Viton® / EPDM / Rubber |

| Motor Options | 1/2, and 3/4 HP |

Pump Features

- Modular Design

- Maintenance Free

- Easy Assembly/Disassembly

- Simple Pin Joint Design

- NPT Discharge Connections

- Low Shear

- Non-Pulsating

Compatibility

Documents

Purchase the LL2 Pump & Parts

Liberty LL2 Pumps

Liberty LL2 Parts

Pumps and pump parts offered for sale by Liberty Process Equipment, Inc. are made in the United States, Germany, India, Spain, Argentina and Brazil.

*Liberty Process Equipment, Inc. is not affiliated with nor distributor for Seepex®, Allweiler®, Moyno®, Tarby®, Netzsch®, or Continental Inc.® All referenced product names, brands, models, or part numbers is solely for identification purposes. Seepex® is a registered trademark of Seepex®. Moyno® and Tarby® are registered trademarks of Robins and Myers® and NOV®, Netzsch® Incorporated is a registered trademark of the Netzsch® Group, Allweiler® is a registered trademark of Colfax® Corporations Continental® Pumps is a Trademark of Continental® Ultra Pumps.